Solution ABC

DAEDOTech Co., Ltd @Copyright

CSS ABC (Accelerated Bridge Construction)

The bridge industry is moving quickly into prefabricated and modular bridges in a preferred way to bridge construction. Accelerated Bridge design and construction is very important for users and clients.

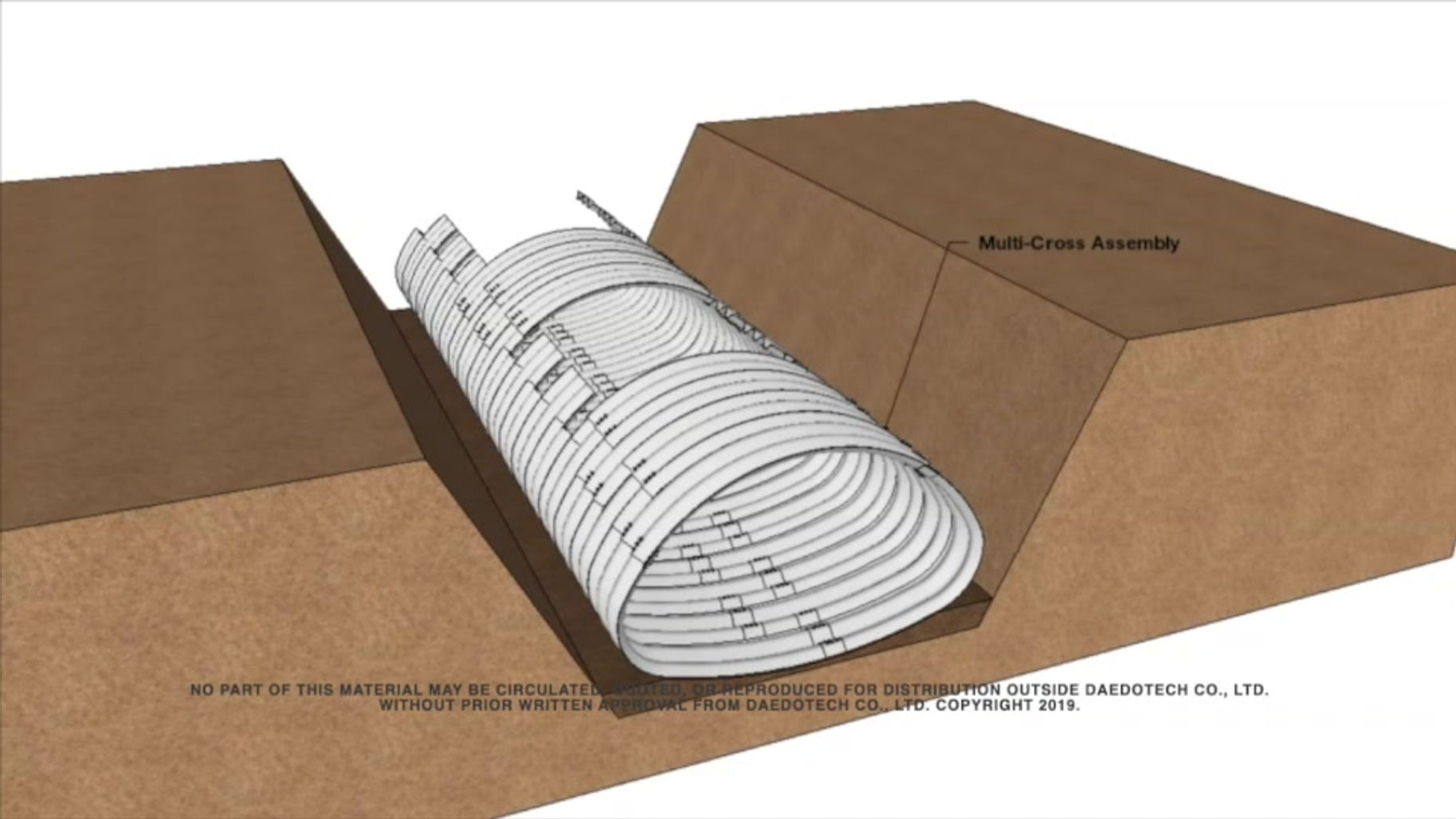

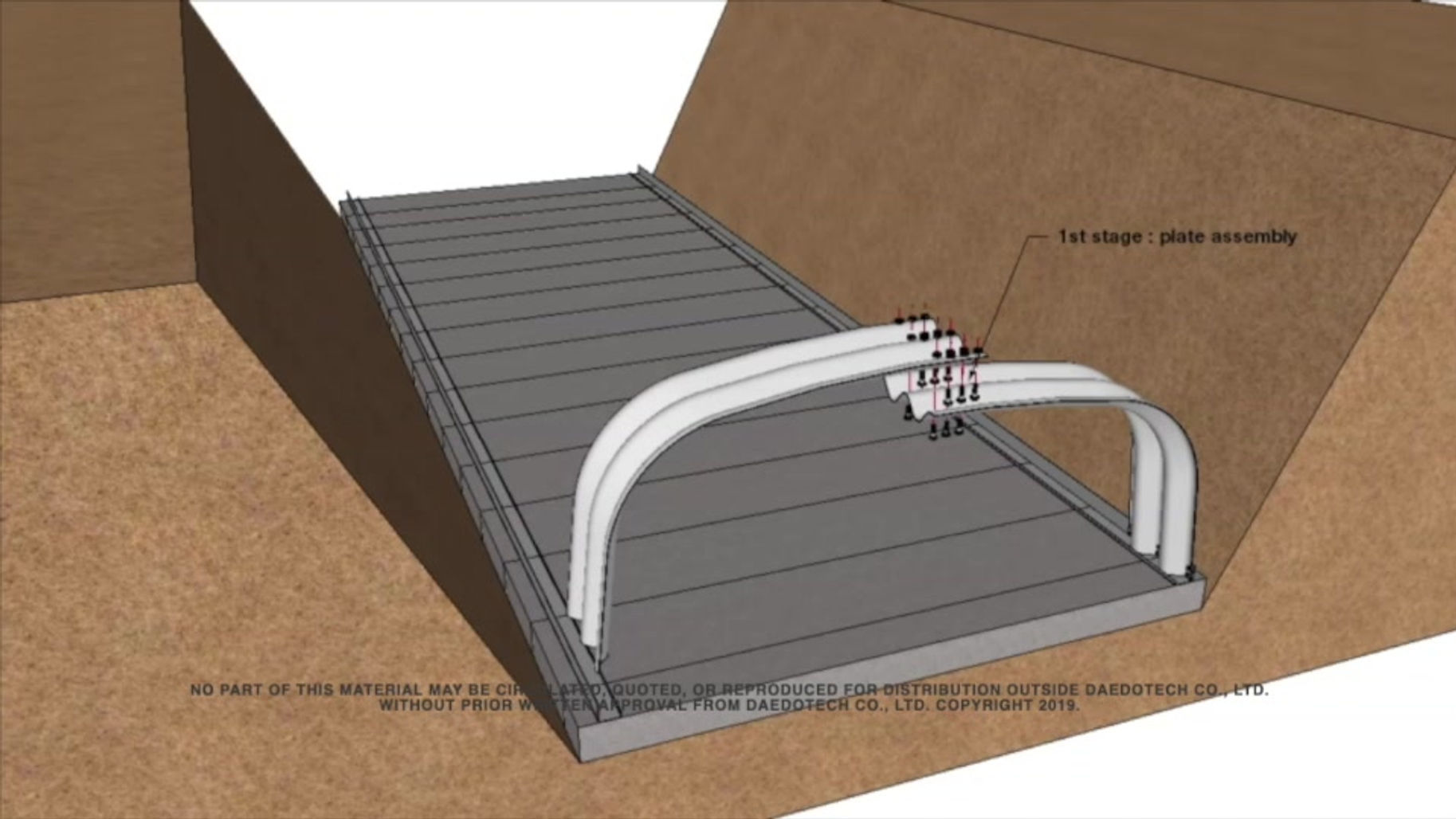

CSS ABC (Accelerated Bridge Construction) provides solutions for many short span bridges. The short span bridges and drains can be designed with prefabricated components that can be quickly built for ease of use locally and are easy to install and can provide significant cost savings. CSS ABC provides long service life with minimal maintenance and offers sustainable benefits comparable to other methods.

Applicable CSS ABC's Short Span Bridge can be designed, manufactured and installed to accommodate a minimum span of 2m to a maximum of 20m (Single Row basis). In addition, it can be installed very quickly in any urgent situation by constructing modular system which is easy to store by container in advance for flood and emergency installation.

DAEDOTech Co., Ltd @Copyright

Round & Pipe arch pipe Specifications

DAEDOTech Co., Ltd @Copyright

DAEDOTech Co., Ltd @Copyright

Box Shape & DSABridge Specifications

DAEDOTech Co., Ltd @Copyright

DAEDOTech Co., Ltd @Copyright

Case Study

DAEDOTech Co., Ltd @Copyright

DAEDOTech Co., Ltd @Copyright

DAEDOTech Co., Ltd @Copyright

Bridge Construction Advantage Comparison

DAEDOTech Co., Ltd @Copyright

Serviceability Comparison

DAEDOTech Co., Ltd @Copyright

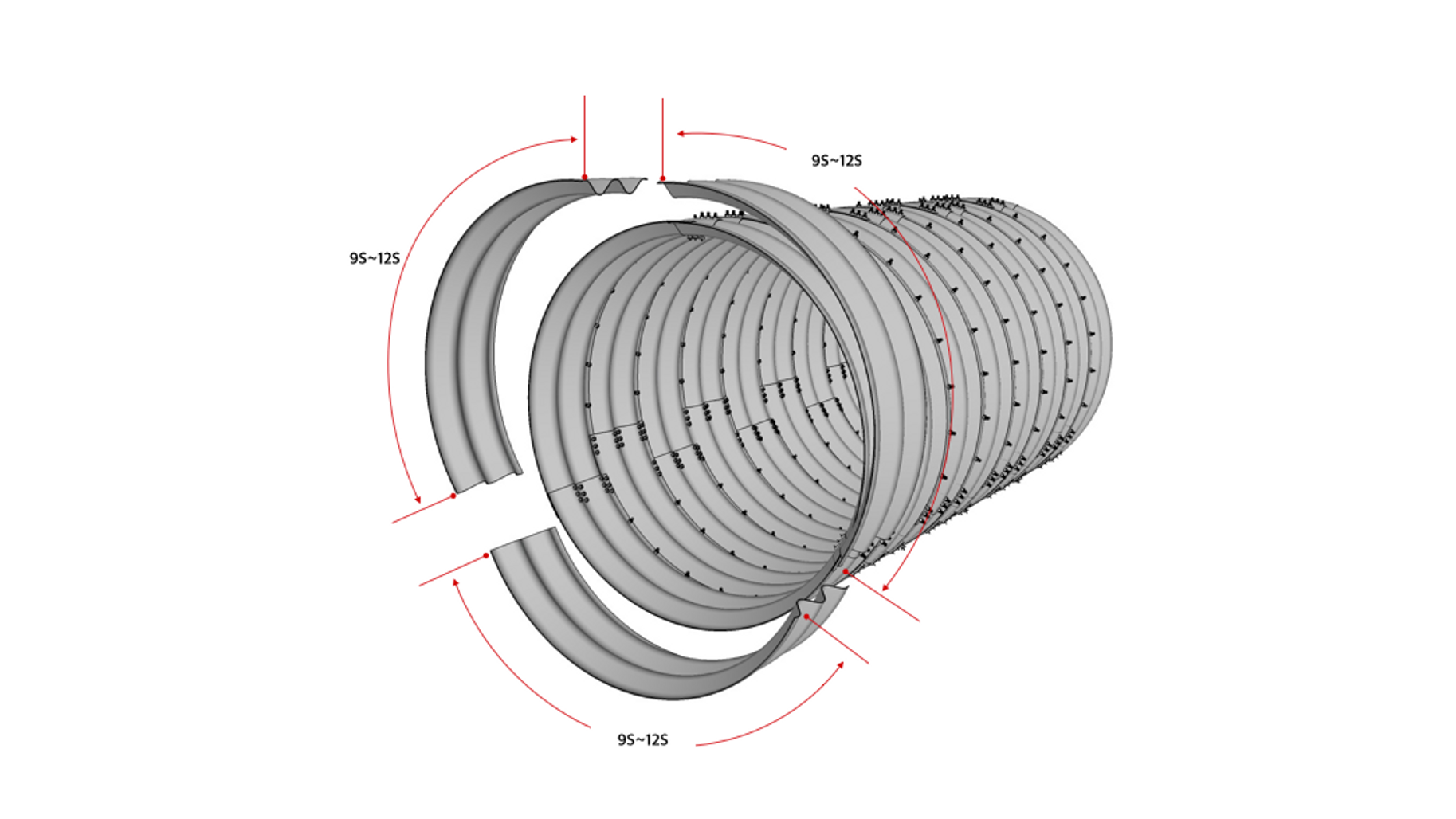

DSABridge® (Deck Slab Arch Bridge)

The existing Box type CSS bridge structure is a mechanical structure with bending moment dominant unlike the axial force governance structure of the Arch type CSS. In order to maintain the cross section of BOX shape type, both side edges (hunch) with the greatest change in curvature occur in the form of a negative moment, and the upper part (Crown) has the structural characteristic to receive the positive moment.

The upper part (Crown) connects the shear connection material connecting the CSS and the slab to the stress relaxation slab to secure the corresponding member force against the positive moment generated at the upper part.

The stress generation range of the hunch part is calculated by measuring the stress range at a certain distance per span and by ensuring the rigidity against the engineering backfill zone by constructing the side wall with high quality soil and filled concrete inside the side wall, .

The design method is designed by the recently revised highway bridge design standard (LSD method, Korea) and it applies the required load (KL-510, HS) and design condition by modeling same as the actual structure using MIDAS GTS NX program.

Traditional Method

DSABridge

Wing Wall

DAEDOTech Co., Ltd @Copyright

Hunch Moment 66% reduced

Hunch Moment

Solution.1

The DSABridge structure can be economically designed as a whole due to the reduced stress on the foundation, as the upper structure is reduced by more than 30% in weight compared to existing typical Rahmen concrete bridges. In addition, due to the rigidity of the CSS ( Reviewed of safety of concrete pouring and curing pressure), it is not necessary to install the slab at the time of casting, and it has superior advantages over the other methods against natural river damages that may occur during construction.

Concrete Colume

12m

CSS

20m

DAEDOTech Co., Ltd @Copyright

DAEDOTech Co., Ltd @Copyright

Solution.2

As the design price is USD830/m2 (Span:20m) based on the upper part of the bridge, it can save about 40% of the construction cost compared with the existing concrete Rahmen bridge (USD1350/m2: *Unit price may vary by country). In addition, based on the optimal cross-sectional library database, it is possible to select a span of 0.4m interval and a height (Rise) of 0.2m spacing, so that it is possible to select a variety of economical sections compared to existing Pre-Fabricated Rahmen bridge (Standard Span Unit: 1m).

DAEDOTech Co., Ltd @Copyright

Keep Final Plan

Patent Registrated: 10-1620513, Patents Pending: 10-2018-0093524